Wet or Dry Operation of diamond blade

How to use diamond blade by wet or dry operation

Wet Diamond blade products must be used with water to keep the segments cool during operation. Water also assists the product to perform at its max, efficiency. Cutting without water on the products will cause

excessive heat resulting in poor performance and diamond blades damage in the form of cracks in the steel center. For concrete floor saws, wet cutting is usually preferred because you can cut deeper when using

water as a coolant. For tile and masonry saws,either wet or dry cutting tools can be used.

Dry diamond blade products must be cooled with airflow around the tool to dissipate the heat.Dry cutting blades are only reccommended for intermittent cutting.

Every 10-15 minutes the diamond blades should be allowed to rotate out of the cut at maximum rpm for serveral seconds to allow the blade to cool. Operators of diamond blade should not use dry diamond blades for long continuous full depther sawing in one single pass. Any cuts deeper than 4cm should be step cutting make serveral shallow passes until the required depther of cut is reached. On asphalt, operators of diamond blade should avoid cutting into the sub base of roads as this will cause rapid wear of the segments. Overheating should be avoided particularly when cutting steel reinforced materials such as lintels, Forcing the product into the application is the most common cause of overheating. If signs of overheating are present, such as blue discolortion at the diamond segment and core, then the diamond blade will require redressing.

Forced cutting of hard aggregates, low abrasive materilas can reduce the cutting ability of the diamond blade. The operator of diamond blade should dress the diamond blade by using it in a soft materials such as sandstone or abrasive blocks which will then restore the cutting properties. For high-speed cut-off saws,dry diamond tools are more poplar, but they are often used wet to control dust. Wet diamond tools and bits Must be used with water. Dry diamond cutting tools may be used either dry or wet, as the job or equipment allows.

Wet Diamond blade products must be used with water to keep the segments cool during operation. Water also assists the product to perform at its max, efficiency. Cutting without water on the products will cause

excessive heat resulting in poor performance and diamond blades damage in the form of cracks in the steel center. For concrete floor saws, wet cutting is usually preferred because you can cut deeper when using

water as a coolant. For tile and masonry saws,either wet or dry cutting tools can be used.

Dry diamond blade products must be cooled with airflow around the tool to dissipate the heat.Dry cutting blades are only reccommended for intermittent cutting.

Every 10-15 minutes the diamond blades should be allowed to rotate out of the cut at maximum rpm for serveral seconds to allow the blade to cool. Operators of diamond blade should not use dry diamond blades for long continuous full depther sawing in one single pass. Any cuts deeper than 4cm should be step cutting make serveral shallow passes until the required depther of cut is reached. On asphalt, operators of diamond blade should avoid cutting into the sub base of roads as this will cause rapid wear of the segments. Overheating should be avoided particularly when cutting steel reinforced materials such as lintels, Forcing the product into the application is the most common cause of overheating. If signs of overheating are present, such as blue discolortion at the diamond segment and core, then the diamond blade will require redressing.

Forced cutting of hard aggregates, low abrasive materilas can reduce the cutting ability of the diamond blade. The operator of diamond blade should dress the diamond blade by using it in a soft materials such as sandstone or abrasive blocks which will then restore the cutting properties. For high-speed cut-off saws,dry diamond tools are more poplar, but they are often used wet to control dust. Wet diamond tools and bits Must be used with water. Dry diamond cutting tools may be used either dry or wet, as the job or equipment allows.

|

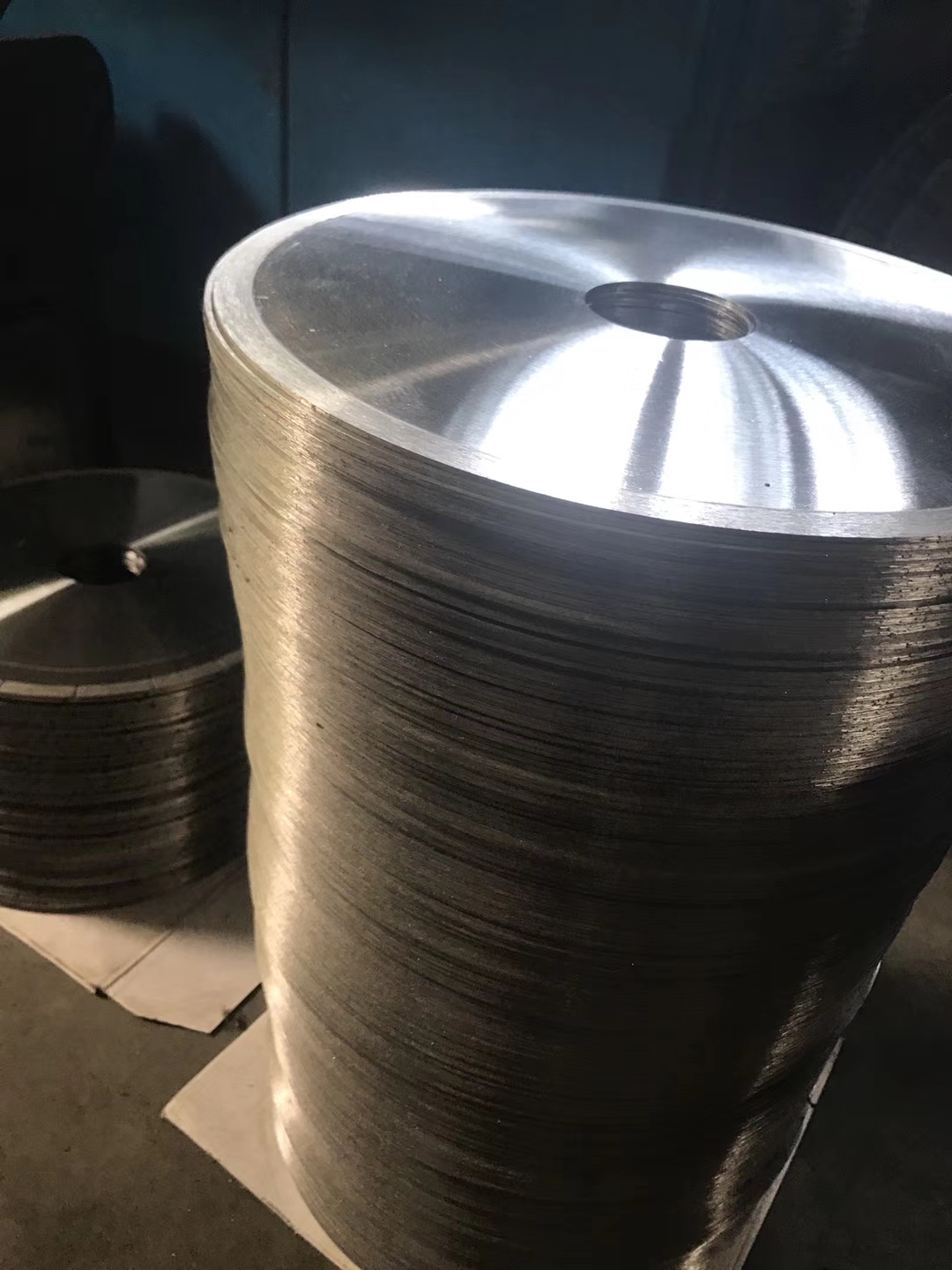

| dry diamond blade |

.jpg)

Comments

Post a Comment

Please make some comments on them. Thanks!!!