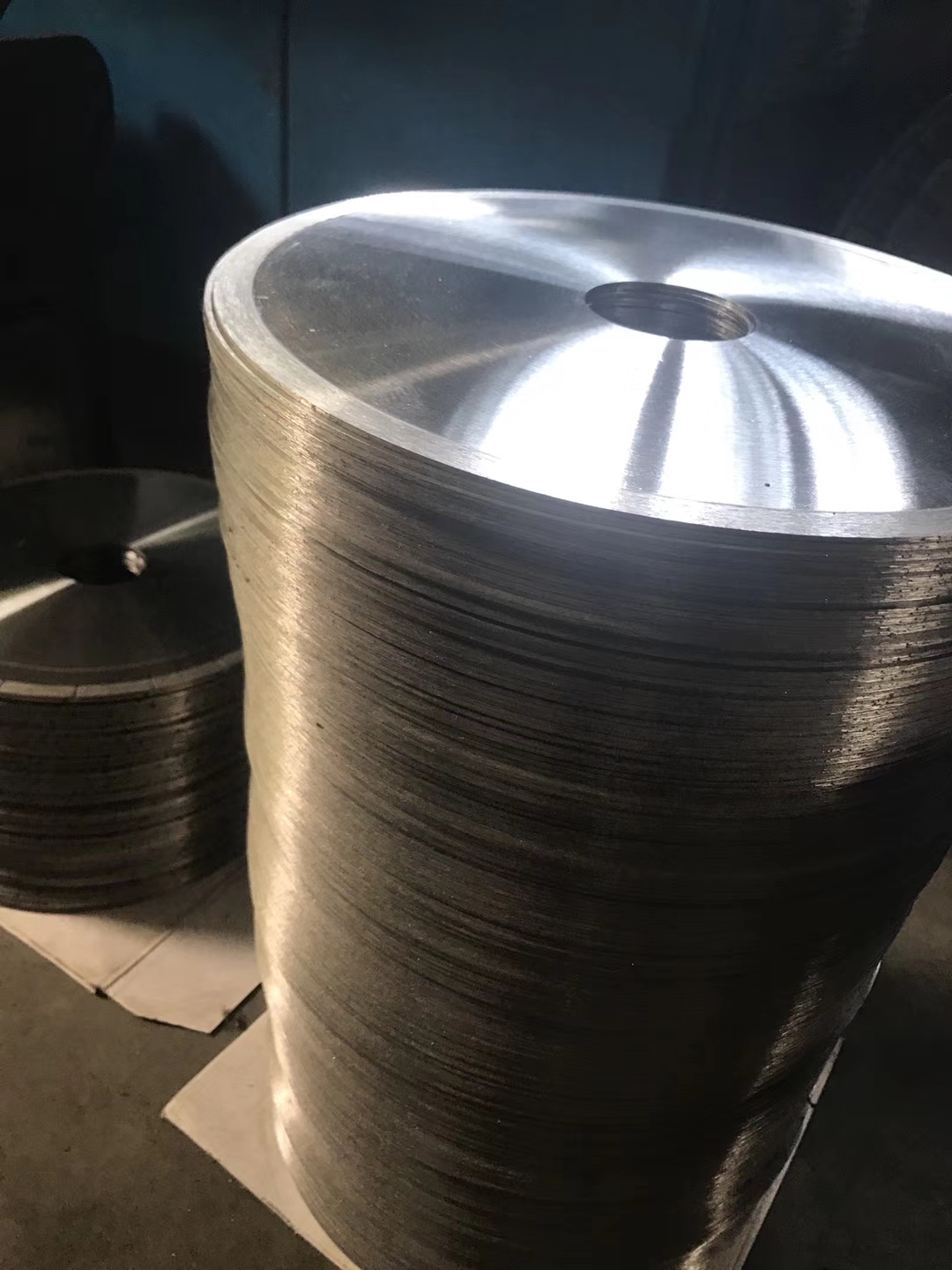

Comparative Chart of Diamond blade with different segment

Diamond Blade with continuous smooth rim provides the smooth cut in ceramic tiles and ornamental stone. Diamond Blade with Segmented or Turbo type may produce slight chipping but generally have a longer life and lower cost per cut than continous rim blades. Segmented Diamond blades provide the longest and lovest cost per cut but only suitable for work where chipping is not a problem. Segmented Turbo ...