Posts

Showing posts with the label concrete cutting blade

Diamond Blade Trouble Shooting Excessive wear

- Get link

- X

- Other Apps

Symptom:Excessive wear of diamond blade Cause:a.Using the wrong diamond blade on highly abrasive material (example: glazed tile blade on concrete block). b.Lack of sufficient coolant to the blade. Often detected by excessive wear in the center of the segment (note: in both above cases, diamonds will usually be highly exposed). c.Wearing out-of-round accelerates wear. Usually can be caused by bad bearings, worn shaft or using a blade too hard for the materials being cut. d.Insufficient power caused by loose V-belts, inadequate voltage, or improper RPMs. Remedy:a.Consult the dealer or manufacturer for the proper blade specification for abrasive material. b.Clean up water system. Make certain water pump is functioning properly. ...

Diamond Blade Trouble Shooting Guide D

- Get link

- X

- Other Apps

Symptom: Loss Tension of diamond blade Cause:Utilizing diamond blade flanges that are under size or not the same diameter, creating uneven pressure on the center. Remedy:Make certain diamond blade flanges are proper size and identical diameter, minimum 3-7/8”, 4-1/2” on concrete saws, 6” minimum on diamond blades that are 30” diameter and larger. Diamond cutting blade

Diamond blade trouble shooting Guide A

- Get link

- X

- Other Apps

This diamond blade trouble shooting guide will help you identify, diagnose and correct diamond blade problems. The following are samples of some of the problems you may encounter in the field, with a cause and remedy guide to diagnose and correct these of some of the problems you may encounter in the field, with a cause and remedy guide to diagnose and correct these problems. Symptom: Loss Tension of diamond blade Cause: Diamond Blade being used on misaligned saw. Remedy:Check for proper saw alignment. Diamond cutting disc

The Grades of diamond blade from JDR Diamond Tools

- Get link

- X

- Other Apps

They are Four Grades for diamond blades to meet different demand from our cutomers: A) Professional Purpose diamond blade : for large civil engineering construction on a regular daily basis, require long life(Less expensive per cut/meter) and fast cutting speed. B) Builder's (Contractor) Purpose diamond blade : for regular cuse with medium life, fast cutting speed no need the same life of a Professional Blade. C) DIY Purpose Diamond blade : For small scale occasional use, require fast cutting speed and reasonable life D) Promotional Purpose diamond blade :cut well with water but with short life. Diamond blade

How to choose the right diamond blade A

- Get link

- X

- Other Apps

Before you get started Decide which is most important to you: the initial price of the blade or the cost per cut. 1.For smaller jobs or occasional use, a low priced Diamond blade may be preferable. 2.For larger jobs or regular use, a higher priced Diamond blade will actually be less expensive to use because it will deliver the lowest cost per cut. For really big jobs, the lowest possible sawing cost (cost per foot) is usually much more important than the initial price. JDR Diamond Tools has a grading system to help you identify the different performance levels of Diamond blades for you to choice Turbo diamond blade

Maximum Blade Cutting Depths of concrete diamond blade

- Get link

- X

- Other Apps

Wet or Dry Operation of diamond blade

- Get link

- X

- Other Apps

How to use diamond blade by wet or dry operation Wet Diamond blade products must be used with water to keep the segments cool during operation. Water also assists the product to perform at its max, efficiency. Cutting without water on the products will cause excessive heat resulting in poor performance and diamond blades damage in the form of cracks in the steel center. For concrete floor saws , wet cutting is usually preferred because you can cut deeper when using water as a coolant. For tile and masonry saws,either wet or dry cutting tools can be used. Dry diamond blade products must be cooled with airflow around the tool to dissipate the heat.Dry cutting blades are only reccommended for intermittent cutting. Every 10-15 minutes the diamond blades should be allowed to rotate out of the cut at maximum rpm for serveral seconds to allow the blade to cool. Operators of diamond blade should not use dry diamond blades for long continuous full depther sawing in ...

How to choose the right diamond blade C

- Get link

- X

- Other Apps

Correctly identify what you’re cutting Correctly identifying the material you are going to cut is the most important factor in choosing a diamond blade . It directly affects the cutting speed and the life of the diamond blade . You will find diamond blade recommendations charts throughout the catalog to help you locate the proper blade for your job. Most JDR diamond blades cut a RANGE of materials. For maximum performance (cutting speed and life), the material should be matched to the diamond blade as closely as possible. As a general rule, determine the material which will be cut most often, or the material for which top diamond blade performance is most important. Diamond blade Diamond cutting blade

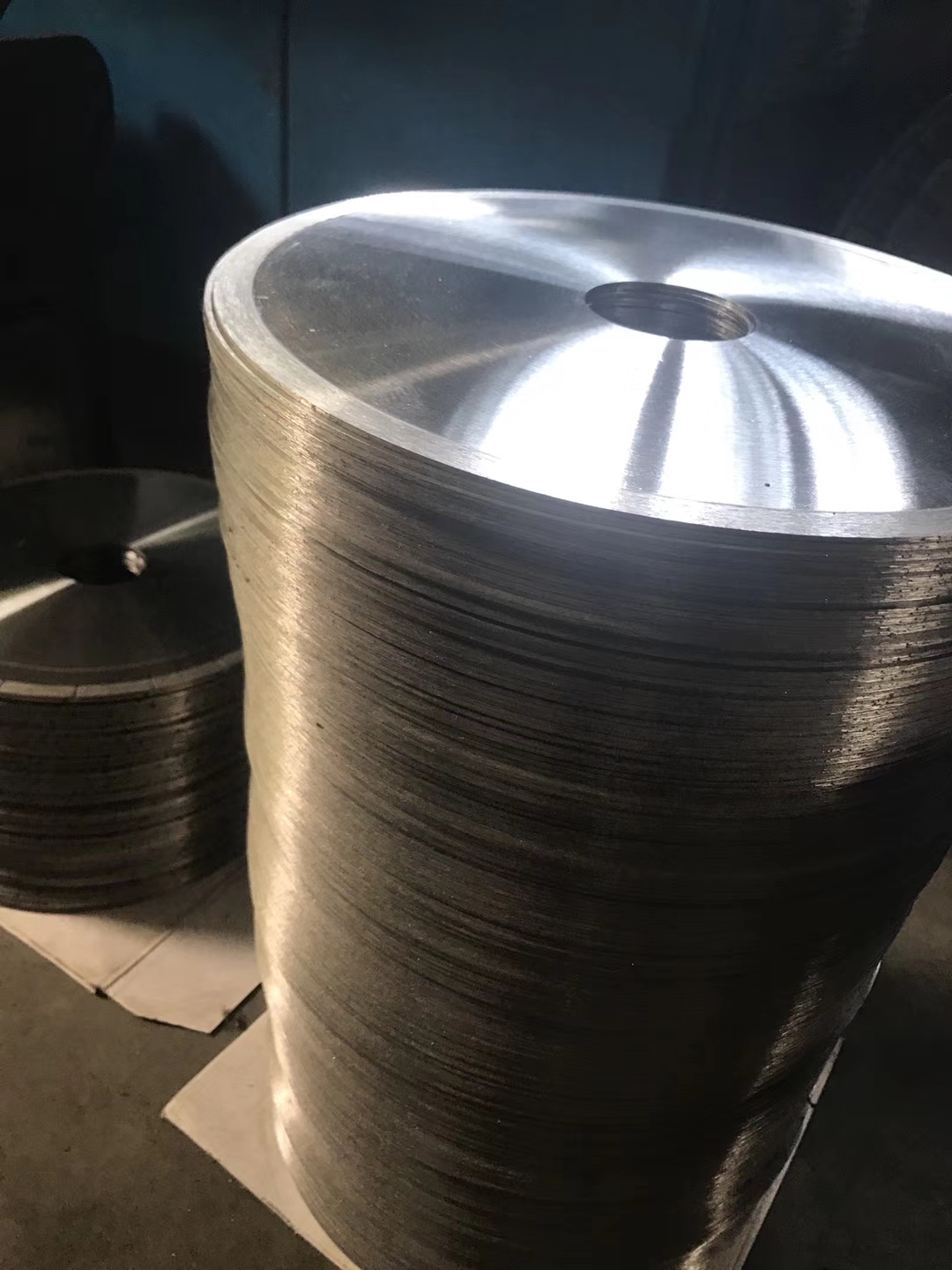

diamond multi blades

- Get link

- X

- Other Apps

1. diamond multi blades 2. diamond multi blades is laser welded or hot pressed to provide optimum performance and good blade life for cutting highly abrasive materials, such as asphalt, green concrete, & block. These diamond blades feature tough wear resistant bonds and hard metal undercutting protection. 3. High exposure rate of diamond on the core of diamond blade to achieve fast cutting speed 4. Drop segmented design for undercutting. 5. Abrasive Materials: diamond multi blades

Diamond Blades

- Get link

- X

- Other Apps

A diamond blade is a saw blade which has diamond fixed on the blade's base or the core to use the diamonds to cut hard or abrasive materials. There are many types of diamond blades, and they have been applied in many industries, for example, construction industry to cut stone, concrete, asphalt, bricks, glass and ceramics, IT industry to cut semiconductor materials, and gem industry to cut gem stones including diamonds. Diamond blade laser welded diamond blade

Maximum Blade Cutting Depths of Diamond wall saw blade

- Get link

- X

- Other Apps

How to select diamond blade for dry or wet cutting by Processing Method way

- Get link

- X

- Other Apps