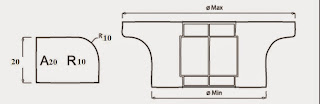

1A1 Diamond Grinding wheel

DIAMOND GRINDING WHEELS for MACHINE BUILDING, ELECTRONICS, TOOL and WOODWORKING INDUSTRIES · Application of 1A1diamond grinding wheel : Used for machining of conical, cylindrical and flat surfaces, cylin drical and conical apertures. Machining of cylindrical surface parts and surface ends at one set up. Machining of recesses and slots of carbide stamps. Sharpening and finishing of carbide tools. · The diamond layer is made of diamond grinding powder in metal or resin bonds. · For metal bonded tools, coolant is required