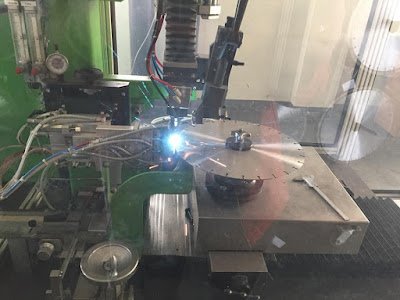

Diamond blades are catalogued by manufacturing method: 1. Electroplated diamond blade Diamonds are electroplated onto the metal blade base. Electroplated diamond blades can be made to be very thin. The thickness of the blade can be tens of microns and can be used in precise cuttings. Actually, the Bond is Nickel. 2. Vacuum Brazed diamond blade Synthetic diamond particles are welded to the outside edge of the circular saw blade via a vacuum brazing furnace. All of the diamond particles are on the exterior cutting edge of the blade, with no metal/diamond mixture. When using a vacuum brazed diamond blade you need not match the type of blade with the material being cut. Depending on the manufacturers recommended blade application, vacuum brazed blades will cut a wide variety of material ranging from concrete to masonry, materials like stone and brick, to steel, various irons, even plastic, tile, wood & glass. Always consult your blade manufacturer for a full list of...